MDH Application Notes

-

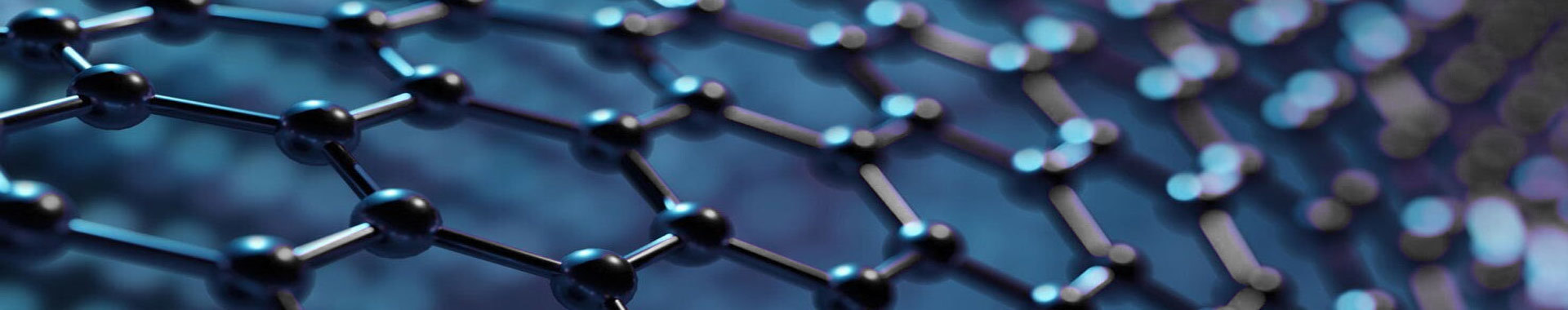

Application Note 1:MDH surface functionalization by polymeric coatings

Test formula (thermoplastic system):

MDH@63%,EVA@32%, compatibilizer@4%, additives@1%Application Note 2: Surface coating improves oil resistance

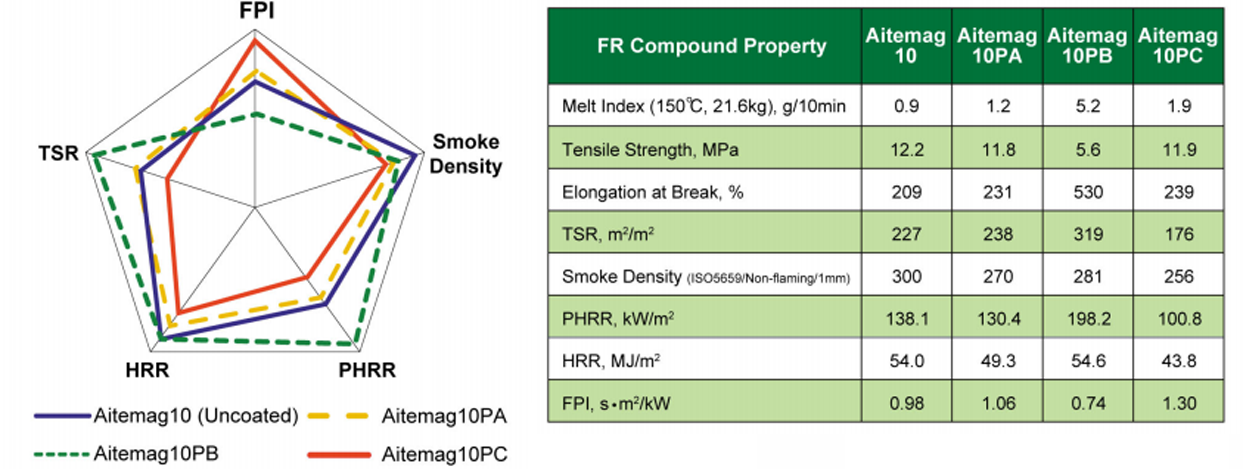

(72h@100°℃,lRM902 fluid)

Test formula (crosslinked system):

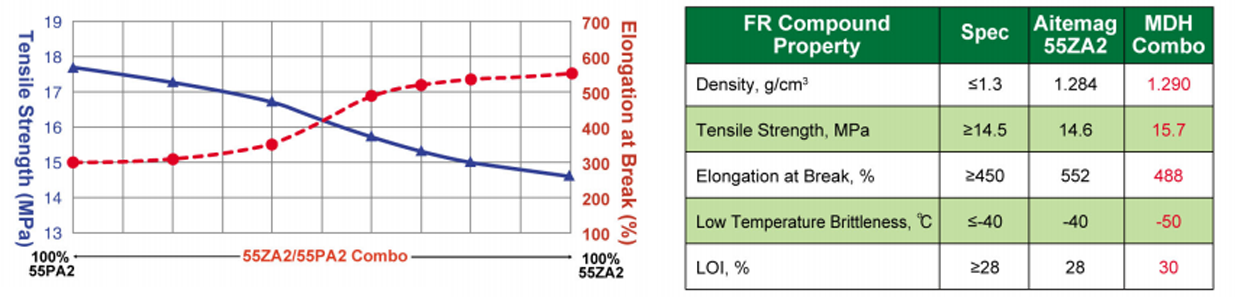

MDH@56%,EVM@32%, LLDPE@7.3%, additives@4.7%Application Note 3: Maximize mechanical property of FR-PE with

magnesium hydroxide COMBO

Test formula (thermoplastic system):

MDH@40%,EVA@29.8%, LLDPE@15%,POE@10%, compatibilizer@4%, additives@1.2%Application Note 4: Aitemag MDH versus imports

Aitemag MDH versus European products

FR Compound Property Aitemag10FM2 European MDH-A Aitemag10PB European MDH-B Tensile Strength,MPa 12.2 11.9 5.3 5.8 Elongation at Break,% 180 160 490 460 LOI,% 41 40 57 55 UL94 Vertical Burn (1.6mm) V0 V0 V1 V1 Low Temperature Brittleness,℃ -50 -55 — — Test formula (thermoplastic system):

MDH@65%,EVA@30%, compatibilizer@4%, additives@1%Aitemag MDH versus Japanese products(1)

FR Compound Property Aitemag10ZA Japanese MDH-A Torque, Nm 25.8 27.0 Melt index(150℃,21.6kg), g/10min 4.2 5.0 Tensile Strength,MPa 9.3 9.1 Elongation at Break,,% 480 490 LOI,% 44 44 Test formula (thermoplastic system):

MDH@60%, EVA@34.8%, compatibilizer@5%, additives@0.2%Aitemag MDH versus Japanese products(2)

FR Compound Property Aitemag10FC Japanese MDH-B Tensile Strength,MPa 12.8 11.6 Elongation at Break,,% 233 208 Melt index(150℃,21.6kg), g/10min 3.4 0.8 LOI,% 38 38 UL94 Vertical Burn (1.6mm) V0 V0 Smoke Density(lS05659/Non-flaming/1mm) 219 214 Test formula (thermoplastic system):

MDH@60%, EVA@34%, compatibilizer@5%, additives@1%

ATK Flame Retardant Materials Company

Address: No. 68 Saite Blvd., Gaocheng Town, Yixing City, Jiangsu Province

Post Code: 214214

Tel: +86-(0)510-87835565

Website: www.aitemag.com

Email:customer-support@aitemag.com

Mobile Website

Copyright: ATK Flame Retardant Materials Company